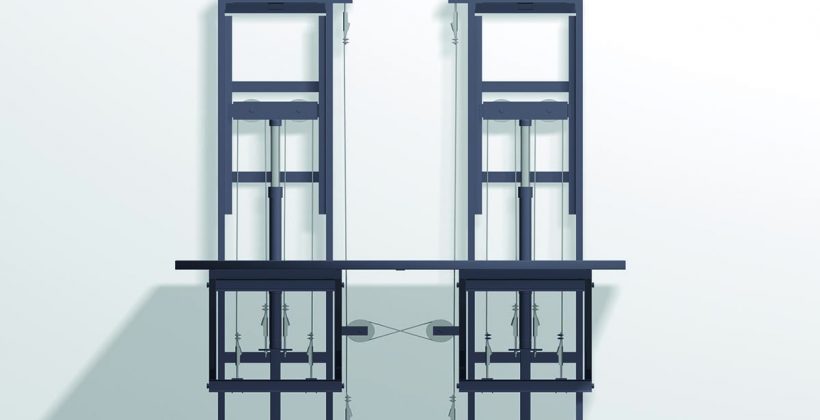

Platform designed to lift only goods by means of two tractor columns placed in line, with a rated load of up to 3000 kg and allowing a wide range of dimensions, lengths of travel and stops.

Its structure allows larger base dimensions, being suitable for vehicles and large volumes. Its inverted chassis configuration allows the platform, as well as its guides, to be flush with the utmost level of the floor.

Possibility of boarding on up to 3 sides.

Range of application

- Rated load from 1500 kg to 3000 kg.

- Rated speed 0,10 m/s or 0,20 m/s.

- Maximum travel 12 m with 2:1 ratio (see travel distances in other ratios).

- Not suitable for the lifting of persons.

Technical specifications

- Drive system by means of two hydraulic cylinders, single acting indirect thrust type (ratio 2:1) and maximum travel of 12 m.

- Drive system by means of anti-rotating steel ropes.

- Rope system compensating for the displacement of the cylinders.

- Rated speed 0,10 m/s.

- Partly pre-assembled 24 VDC electric operation. Two-stop control via electronic board. For three stops or more and for special options (sliding doors, re-levelling etc.) by means of a programmable logic controller (PLC), allowing great versatility of functions and extras.

- Non-slip steel floor.

- Possibility of up to three boarding sides.

- Three-phase electric motor.

- Landing push buttons control panel with mushroom stop button.

- Supply of separate chassis base.

- “Grey hammer effect” finish.

Safety systems

- Control of slackening ropes by electrical safety contact.

- Mechanical final limit safety contact.

- Pressure relief valve.

- Hydraulic rupture valve on each cylinder.

- Timer control for excessive operating time.

- Protective guards on side of guides on the entire length of the platform.

Options

-

- Rated speed 0,20 m/s (see, for more).

- Two-piece cylinder. Recommended for distances of over 11 m (ratio 2: 1).

- Distances of over 12 m in other ratios (see).

- Mechanical safety gear installation on the platform chassis.

- For heavier loads (see): use of balancing system of columns depending on load and dimensions.

- Side protection: in tube, tube and sheet or sheet in carrier.

- Rail system structure focused on the meat industry.

- Re-levelling: normal or with two motors. Keeps the platform flush with the floor during loading and unloading processes.

- Door security system using electric lock (see others).

- Light curtains or photoelectric cells on boarding items (subject to placement and type of guards).

- Emergency back-up (to lower the platform to the ground floor).

- Resistance to overheating.

- Recessed landing push buttons control panel.

- Drive system using chains.

- Anti-corrosive treatment by hot galvanising and finishing in stainless steel sheet (see other finishes).

- Manual double-leaf doors or articulated slats.

- Electric anti-creep system that allows the platform to be left stationary, at each stop, for loading and unloading.